Patented special milling system

(DFM – Dyk Flour Milling)

Beginning of the 80´s, long before the boom on the health-food sector started, the DYK-Mill begun with the production of whole meal flour. A special milling system was developed, where the kernel could be milled as a whole, instead of separating the germ bud, stabilizing it by heat treatment and returning it back to the flour, as to prevent this from getting rancid.

With this patented milling system, it was achieved to de-activate the fat splitting enzymes of the kernel, without destroying the vitamins, as done in the case of conventional milling. This way, high quality whole meal flour is produced with a shelf-life of at least 9 months

Advantages

- Keeping the vitamins and vital substances!

- Only after 6 months a noticeable decomposition sets in and even after 9 months only about 50 % of the vitamins are affected.

- The starch exposure degree can be regulated!

- Potential larvae or eggs of varmints (if accidentally present in the grain) are 100% destroyed by the special milling system.

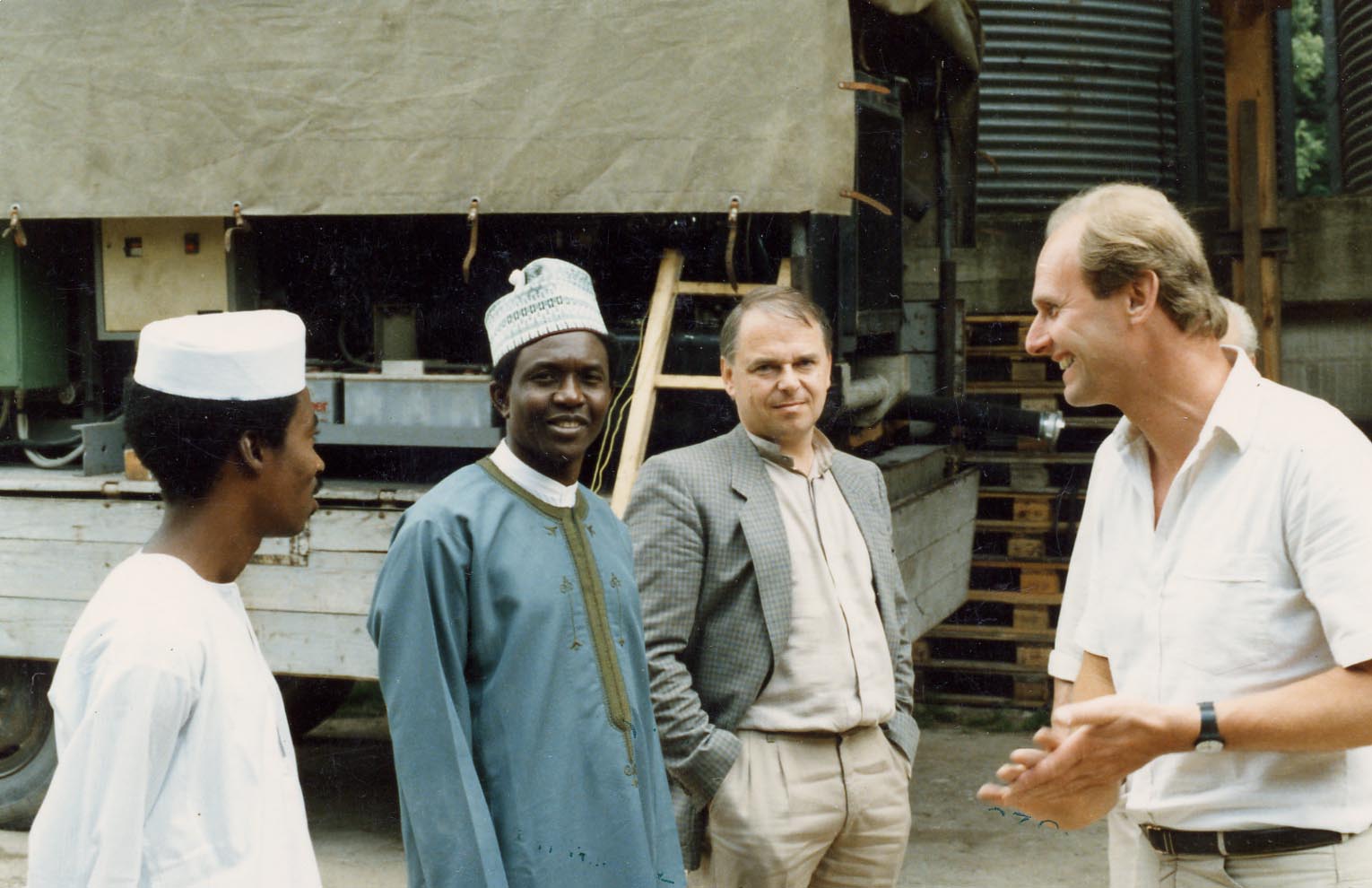

To share this technology and its benefits, our company Compact Milling Systems (https://cms-milling.com) exports mills all over the world.

Technology comparison

Conventional roller-milling

Grain cleaning:

Impact-scouring. The valuable germ buds are mostly knocked off and separated for feeding purposes.

Milling:

Grain is crushed by fluted roller-mills through squeeze and shearing power. This kind of crushing takes place on so-called roller-mills, whereby the milling of the grain is done by two parallel running rollers, which are arranged adjustable to each other and which have a fluted surface.

To reach the desired fine flour quality, 20 – 25 steps (= roller-mills and plansifter sections!) are needed with this kind of system, whereby each step consists of crushing and sifting.

Patented special milling system (DFM – Dyk Flour Milling)

Grain cleaning:

Gentle wet-scouring. When cleaning wheat and rye the valuable germ buds (with their high content of vitamins and trace elements) remain and are stabilized in the flour through the patented CMS-process!

Milling:

The CMS milling-system uses a combination of roller-milling and impact grinding. The first crushing step, as in conventional systems, takes place on fluted rollers (just 1 roller-mill). Whereas in the connected sieving on the plansifter, the milling product is sorted out into coarse bran, semolina and flour. The further milling takes place in 2 patented steps only on desintegrators (double effective pin-mills).

They disintegrate the milling product through impact (whereby a max. milling-product warming of only 28° Celsius follows). The free impact leaves the elastic elements (= coarse bran particles) complete, but friable/inflexible elements (= semolina) of the endosperm-parts of the grain corn are milled to

flour in one operation only.

This CMS-method guarantees that only the optimum of each crushing-procedure is applied!

Advantages:

- Keeping the vitamins and vital substances!

- Only after 6 months a noticeable decomposition sets in and even after 9 months only about 50 % of the vitamins are affected.

- The starch exposure degree can be regulated!

- Potential larvae or eggs of varmints (if accidentally present in the grain) are 100% destroyed by the special milling system.

Interview with Peter Dyk

Interview with Mr. Peter Dyk on his special developed milling system (DFM – Dyk Flour Milling)

What is so special about this new milling system?

This new milling system is segmented into a pre-crushing process (same as in a conventional mill) and in the separation of shells, semolina and flour. The shells are being milled on a pin-mill and the result is dark flour. The semolina is milled on a separate pin-mill and you get white flour. The dark flour is used for baking bread and the white flour for buns and cakes etc.

That means one gets dark and light flour from the same corn?

Yes, and if you want to leave the shell on the grain, which is possible of course, and the grain is properly cleaned, you can mill it on a pin-mill to get a whole meal flour with a shelf-life of at least 9 months! The reason is that, with our special milling system, the fat splitting enzymes are stabilized by the power strike of the pin-mill. In the conventional milling process the shells must be removed due to shelf-life problems.

When this problem is solved, the value of the whole corn is kept?

During conventional milling on roller-mills, the germ bud must be separated as the enzymes stay active and if one does not remove the germ bud, the flour will turn rancid rapidly. The enzymes cause, in connection with oxygen, the oxidation of the fat and the fat turns rancid and spoils the flour.

How did you get the idea to develop this new milling system?

From 1970 to 1971 I spent a year in South Africa and there I have realized that fibers are mixed in to the flour for health reasons. I also became aware of the fact, that one day in Austria there will be a few big mills dictating the prices and that a small mill, like ours, will not be able to prevail on the market with just ordinary flour. The only possibility would be to specialize! When I returned from South Africa, my first idea was to produce flour from which one cannot get fat. I was thinking about flour with less starch and higher protein content. When one has to digest protein, one needs more energy and, on this base, one will not get fat! Technically the baking process was a success, but the high protein content caused endless chewing as protein is not soluble in water and it was like chewing gum – the piece of bread in your mouth never got less!

My next idea was to add fiber to flour and make whole meal flour, but with the conventional roller-milling, the germ bud got rancid. The research was done with help of the Austrian Research Fund. The question was:” How to produce whole meal flour at low costs” and “How can the vital substances, like vitamins and trace elements survive?” Together with an engineering company and the Research Institute for Nutritional Science, many tests were carried out. During this project, we found the solution in stabilizing the enzymes by means of a mechanical bashing process, through which the shelf life of the flour remains for more or less nine months. This was the first step towards milling by means of a pin-mill. Naturally this milling system has been improved and after a while, it was possible to produce extraction flour. Extraction flour is flour, where the white center kernel is milled and the bran is sieved separately. This milling system is so simple and short that it can be installed in a 20 foot container with a 1800 kg per hour capacity. These so-called CMS-Mills (Compact Milling Systems) are produced in Austria.

If interested, please check: www.cms-milling.com

How does the quality of the flour milled by this new system compare to that milled by conventional roller-mills?

The quality of the flour – concerning the baking-ability – is exactly the same as flour milled on a conventional roller-mill. The CMS-mills do have one advantage though, through the fine grinding in the pin-mill, the starch parts also get broken and these parts absorb more water than flour milled on a roller-mill. Therefore the baker has a higher dough yield, as he can put more water to the flour. Also the germ bud is not sieved out, but remains in the flour and the extraction flour shows a higher vitamin content.

Is there a price difference per kilogram flour?

The difference is in the purchase costs. The price for our Short Milling System is about 50% of a conventional roller-mill and on top of that, for a conventional mill you need a multi-storey building, for our mill you only need a hall. The plant is also much easier to supervise, control and to maintain.